First, we would like to thank you so much for your past orders if you have placed one. They are the life’s blood of our Handcrafted in the USA business. You get a one of a kind gift, and we get to make an honest living doing something we are extremely passionate about.

Like most businesses these days, you will find Relic Wood on most popular social media outlets getting the word out about our handcrafted products.

We are extremely proud of the fact that we employ local craftsmen, buy American made equipment, locally source our materials, and work hard every single day to make sure our customers are 100% satisfied with their purchases from us. If not, we make it right. Each of these things are crucial for our continuing success as a company.

On social media, we find that there is tremendous amount of positive feedback, funny comments, some constructive criticism, and occasionally, snide comments on our posts about the cost of our products. This morning while combing our social media accounts to see if anyone who had commented needed help or more information about our products, we found this gem of a comment referring to the price of our products.

The comment read, “$129.00… I can make that myself for about $30.00 in materials, if that much.” It was so simply stated, that it almost sounded like truth – EXCEPT for the fact that it did not count the actual cost.

We are talking about the “Actual Cost” of making the piece they were referring to. The statement discounted the fact that this person believed that they already owned all the industrial woodworking equipment, specialized tools, and shop area needed to produce an exact copy of the product. I assure you that they did not. It did not include any cost for the physical labor required to make it, or the time spent designing and sourcing our quality local materials and hardware. It did not include the cost of finding a buyer through advertising or the cost of customer service if for any reason the buyer didn’t like it. Most importantly, their meager cost estimate did not include the tremendous amount of money for the woodworking equipment. Nor did it include the years of time and training to master our woodworking craftsmanship. I am talking about the knowledge of setup & proper use of ALL the different equipment used to create our gifts, and the skills involved with running it safely.

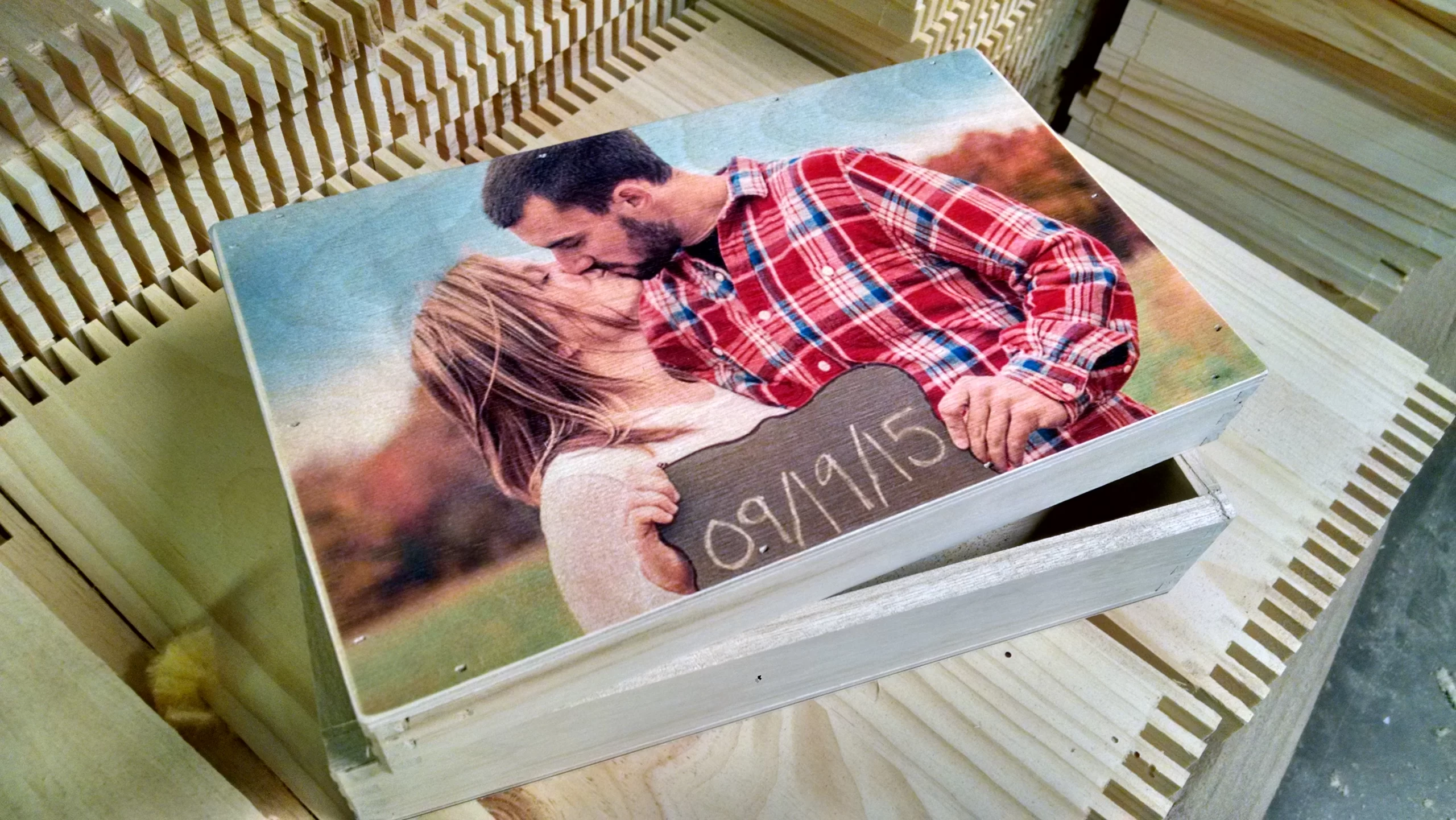

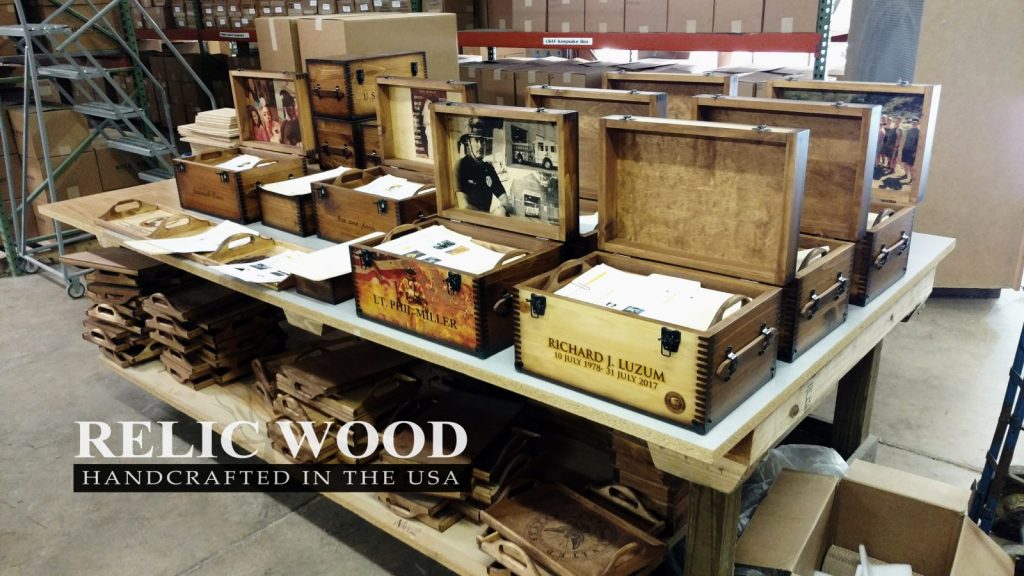

At Relic Wood, we aren’t making just one wooden box in a little wood shop behind our house with no custom artwork. Due to the constant demand for our products, we operate a 24,000 sq. ft. Manufacturing Facility and very proud to currently have 12 full time employees. We make thousands and thousands and thousands of custom wooden gifts every year in lots of different styles and a wide variety of product sizes.

So what is the actual cost?

For those who think we are all driving Lamborghini’s from our massive markup, and ready to jump into the business, unfortunately you will be sorely disappointed. Our end cost is actually very close to the price we end up charging on our website. Manufacturing in America is not cheap. Here is why. As a business that wants to stay in business, Relic Wood invests in very high quality woodworking equipment to ensure the beautiful results our customers love. By woodworking equipment, we mean multiple table saws, hand routers, dado blades, band saws, wide belt sanders, miter saws, air compressors, laser engravers, a huge variety of pneumatic tools, wide format haunchers, overarm routers, a huge selection of router bits, carts to move products inside our shop, specific purpose saw blades of varying size and kerfs, finishing spray booth, filters, dust masks, protective eye wear, safety equipment, finish spray equipment, drills, stain tanks, part jigs, lots of hand power tools, as well as the massive building to put all that equipment in and to work in. Some of it costs thousands of dollars for one piece of equipment, while others are less expensive. Our latest major equipment purchase was over $169,000 for just one machine. With little to no down-time from our machines and equipment, we can deliver on our promises of excellent craftsmanship to our customers and do it in a timely manner.

If that was all we had to worry about paying, our costs would be less . . . but that is just the beginning.

We have accounted for the cost of equipment, but there is also all the different materials that we always keep in stock to fill our orders. Lots and lots of wood of all different shapes and sizes. The cost of our wood stock alone would scare you. Many screws in different sizes and lengths, staples of various sizes, nails, multiple colors of felt, rolls of cork, sheets of luan, plywood, stain, sealer, lacquer, stain rags, poker chips, glassware, decks of cards, metal corners, lot of different screws, brass nameplates, brass plaques, drill bits, large format printers, ink, maintenance cartridges, specialized paper, print heads, sandpaper of various grits, barrels of wood glue, down to the drops of oil to put in our nail guns and staplers. We keep our sandpaper fresh, our saw blades and router bits sharpened, machines serviced, and plenty of hand picked wood in steady supply to fulfill our orders.

Now lets count the time and labor needed to make our products. After all, no one here shows up and works for free. It is our profession, not a hobby shop. Relic Wood is a family owned business, not some big corporation with bottomless pockets and stock holders begging for more profit at the expense of our products quality. We don’t brand our products “Handcrafted in the USA” and then deceive our customers by using dirt-cheap foreign labor to actually make them. Our talented woodworking craftsmen and staff are a tight knit group of relatives, old high school friends, a couple greenhorns, and ALL of them have families to feed and taxes to pay. Every single custom gift is made one at a time . . . just for you. No one that works here makes minimum wage and never will.

Our Relic Wood staff is not just comprised of woodworking craftsmen however. We also staff graphic designers, customer service representatives, quality control, shipping personnel, and managers. Relic Wood is also a Veteran owned business. Meaningful work is why we show up to work each day. Dedication to creating something special, something sentimental, something made by hand in America by Americans is important here. Our products are so well built they can be passed down generations.

Now we have covered equipment, materials, and labor. We are done counting the costs right?

We wish! Next comes the ongoing business expenses. We are talking about expensive business and workers compensation insurance, income taxes, sales taxes, accountant fees, matching our employees FICA, Medicare, our phone bills, internet bills, power bills, heat, air, water bills, building lease, computers, software, website development, dedicated web servers, ridiculously expensive advertising, search engine optimization, fire safety equipment, inspection fees from the fire marshal, just to name a few regular business expenses as this is by no means a complete list.

Shouldn’t we be charging MORE?

Nope. We know our boxes are fairly expensive already. While we wish everyone would buy one, we also know that not everyone can afford to buy one, and that is OK with us too. Our goal is not to make massive amounts of money, but to operate our business with Integrity and treat our customers the way we want to be treated. At Relic Wood, we know that when we are dead and gone, what we do inside our shop each and every day, will still have sentimental value to those who choose to purchase from us and can be passed down generations.

We get to make an honest living in the meantime.

PS. For those of you who are lucky enough to have a woodworking hobby shop behind your house and are hating on social media . . . Stop hating and get to building. We are sure it will turn out nice.